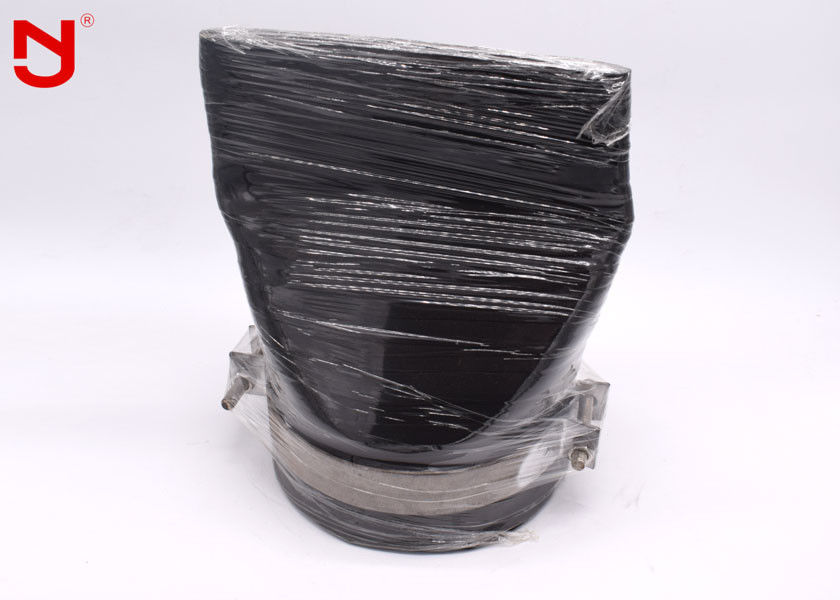

Dn150 pn16 natural rubber thermal expansion valve one-way valve

Rubber blowdown check valve is also known as rubber flexible check valve, as the valve is shaped like a duck's bill, is often called a duck's bill valve. Duck bill valve is widely used in urban drainage and drainage system and sewage pipe network. Duckbill valve is a one-piece structure, 100% rubber material, with a nylon cord rubber cover built in, without any mechanical parts. The valve has good opening and closing characteristics. It only controls the valve opening and closing by internal pipeline pressure and external back-pressure. The valve is completely resistant to sewage corrosion. When the valve is closed, the leakage is zero and the sealing performance is good.

Product Application

Rubber drain check (duck bill valve) is widely used in beach, beach, pier flood, waste water, and coastal city sewage discharge. Rubber blow check valve (canard valve) can replace clapper check valve. Rubber drain check valves under DN800 are recommended to be either clamped or flanged. Rubber blow-down check valves for DN800 or above are recommended for flanged connections.

Rubber Duckbill Valves is a very reliable and cost effective check valve compare to flap check valves and other conventional check valves.This valve is a special product ,and it is used for draining sewage .In many foreign countries,such as Spain , America,it is usually named as duckmouth-shaped valve .We are doing our best to make this valve more practical and more perfect .The valve can be matched with steel pipe ,cement pipe .At the same time ,they may be widely used on the coast,seasands,reservoirs,and so on.In order to dispose the sewage or to dredge the floods.

Application:

Mainly used in water systems,drainage systems,outlet of water pumps and upgrading the pumping station and liquid aeration system.Rubber flange and valve body are as a whole, so the installation is very convenient.The valve body is designed with a full rubber, which will not cause siltation and stickin. It reduces the maintenance cost, and allow the solid particles to pass smoothly.

Specification

For BS EN1092-2 PN10/16 flange mounting.

Face-to-Face dimension conforms to ISO 5752 / BS EN558.

Epoxy fusion coating.

| 1.Material |

EPDM,NBR,CR,KFM,VITON,PTFE, |

| 2.Construction |

inner core,outer cover,frame,metallic ring, |

| 3.connector approval |

flange,flange type,threaded type flexible coupling rubber |

| 4.type |

single sphere,double sphere and reducing sphere, |

| 5.threads |

BSPT ,BSP,NPS,NPT,Metric |

| 6.flange drilled |

BS,ANSI,DIN,JIS,UNI,or others provided drawings sample |

| 7.surface |

galvanized ,epoxy |

| 8.normal size |

single sphere(DN32-DN3000),double sphere(DN32-DN1200)threaed flexible coupling rubber (DN15-DN80) |

| 9.usage |

protecting piping and equipment system from stress or motion |

Features & Benefits

1.Automatically open and close according to pressure differential pressure,safe and reliable,no noise,no need of persoonnel to operate,no maintenance.

2.Forward turn-resistance ,a small start-up pressure and flow naturally adjusted according to the water pressure.

3.Reverse backstop sealed,no leaks,it prevents backflow,the greater the back pressure,the better the results.

4.Anti-corrosion,anti-aging,deformation,adaptability,long service life

5.A wide range of sizes,nominal diameterDN50-DN3000

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!