Flapper Valves Umbrella Valves Duckbill Valves and Custom Rubber Check Valves

One-way sealing valves are used to facilitate a unidirectional flow of fluid. Depending upon the application this either causes a forward flow or prevents backflow in a device. Our flapper, umbrella, duckbill and custom valves are produced from a wide variety of rubber compounds, including medical and food-grade silicone and hydrocarbon-resistant rubber in order to handle a broad range of tolerances and temperatures.

All one-way rubber sealing valves allow fluid, either a liquid or a gas, to flow through it in only one direction. The design and structure of one-way check valves make them widely applicable in pressured fluid environments. The elastomeric compound offers itself to be low-maintenance, rust-free, and highly responsive to very subtle pressure changes. Flapper Valves accomplish this by containing a hinged flap or disk that swings in one direction only. Umbrella Valves feature a ball or rounded shaped end which snaps easily into a mating plate or receptacle. Duckbill Valves allow positive pressure to open the valve and negative pressure to close off flow. Our custom one-way rubber valves offer a solution to unconventional unidirectional flow requirements.

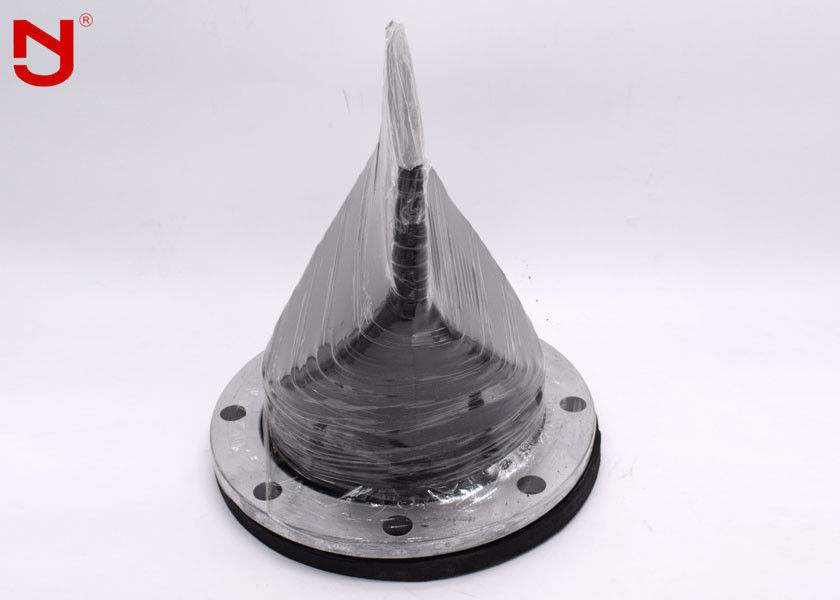

Rubber Duckbill Valves is a very reliable and cost effective check valve compare to flap check valves and other conventional check valves.This valve is a special product ,and it is used for draining sewage .In many foreign countries,such as Spain , America,it is usually named as duckmouth-shaped valve .We are doing our best to make this valve more practical and more perfect .The valve can be matched with steel pipe ,cement pipe .At the same time ,they may be widely used on the coast,seasands,reservoirs,and so on.In order to dispose the sewage or to dredge the floods.

Specification

For BS EN1092-2 PN10/16 flange mounting.

Face-to-Face dimension conforms to ISO 5752 / BS EN558.

Epoxy fusion coating.

| 1. Material |

EPDM,NBR,CR,KFM,VITON,PTFE, |

| 2. Construction |

inner core,outer cover,frame,metallic ring, |

| 3. connector approval |

flange,flange type,threaded type flexible coupling rubber |

| 4. type |

single sphere,double sphere and reducing sphere, |

| 5. threads |

BSPT ,BSP,NPS,NPT,Metric |

| 6. flange drilled |

BS,ANSI,DIN,JIS,UNI,or others provided drawings sample |

| 7. surface |

galvanized ,epoxy |

| 8. normal size |

single sphere(DN32-DN3000),double sphere(DN32-DN1200)threaed flexible coupling rubber (DN15-DN80) |

| 9. usage |

protecting piping and equipment system from stress or motion |

Features & Benefits

1. Automatically open and close according to pressure differential pressure,safe and reliable,no noise,no need of persoonnel to operate,no maintenance.

2. Forward turn-resistance ,a small start-up pressure and flow naturally adjusted according to the water pressure.

3. Reverse backstop sealed,no leaks,it prevents backflow,the greater the back pressure,the better the results.

4. Anti-corrosion,anti-aging,deformation,adaptability,long service life

5. A wide range of sizes,nominal diameterDN50-DN3000

Application:

Mainly used in water systems,drainage systems,outlet of water pumps and upgrading the pumping station and liquid aeration system.Rubber flange and valve body are as a whole, so the installation is very convenient.The valve body is designed with a full rubber, which will not cause siltation and stickin. It reduces the maintenance cost, and allow the solid particles to pass smoothly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!