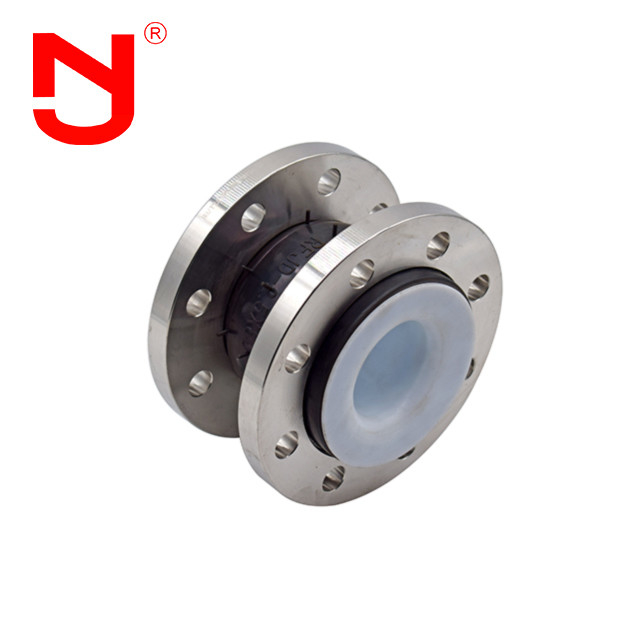

PTFE Expansion High Pressure Resistant Rubber Flexible Joint Bellow In Piping Customized

Product Description

For industries demanding contamination-free fluid transfer, the PTFE Flexible Joint Pipe sets new benchmarks in purity and reliability. The seamless PTFE liner undergoes ultra-high molecular weight processing to eliminate porosity, ensuring compatibility with ultra-pure water (UPW), photoresists, and corrosive gases. Reinforced with AISI 316L stainless steel or Hastelloy® alloy braiding, the assembly withstands pressures exceeding 40 bar while maintaining burst strengths up to 160 bar. This dual-layer architecture provides exceptional flexibility in cryogenic applications down to -200°C, making it suitable for LNG transfer, pharmaceutical cryogenic storage, and aerospace fuel systems. The patented convoluted bellows design further enhances vibration damping capabilities, critical for reducing particle generation in semiconductor fabs.

Performance characteristics

1. Flexibility: Accommodates axial, lateral, and angular movements.

2. Durability: Reinforced rubber flexible joint provides long-lasting performance.

3. Corrosion Resistance: Resists aggressive environments and chemicals.

4. Noise & Vibration Reduction: Dampens vibrations and shock waves.

5. Ease of Installation & Maintenance: Compact design and standard flange connections facilitate installation and upkeep.

Product Specification

| Size |

Length |

Allowable Movements in Operation |

| mm |

inch |

mm |

Axial Compression mm |

Axial Extension

mm |

Transverse Movement

mm

|

Angular Deflection mm |

| 25 |

1 |

130/152 |

20 |

12 |

14 |

15° |

| 32 |

1 1/4 |

95/130/152 |

20 |

12 |

14 |

15° |

| 40 |

1 1/2 |

95/130/152 |

20 |

12 |

14 |

15° |

| 50 |

2 |

105/130/152 |

20 |

12 |

14 |

15° |

| 65 |

2 1/2 |

115/130/152 |

20 |

12 |

14 |

15° |

| 80 |

3 |

130/135/152 |

20 |

12 |

14 |

15° |

| 100 |

4 |

130/152 |

20 |

12 |

14 |

15° |

| 125 |

5 |

130/152/165 |

20 |

12 |

14 |

15° |

| 150 |

6 |

130/152/185 |

20 |

12 |

14 |

15° |

| 200 |

8 |

130/152/210 |

20 |

12 |

14 |

15° |

| 250 |

10 |

130/203/230 |

20 |

12 |

14 |

15° |

| 300 |

12 |

130/203/245 |

25 |

16 |

22 |

15° |

| 350 |

14 |

200/255 |

25 |

16 |

22 |

15° |

| 400 |

16 |

200/255 |

25 |

16 |

22 |

15° |

| 450 |

18 |

200/255 |

25 |

16 |

22 |

15° |

| 500 |

20 |

200/255 |

25 |

16 |

22 |

15° |

| 600 |

24 |

260 |

25 |

16 |

22 |

15° |

| 700 |

28 |

260 |

25 |

16 |

22 |

15° |

| 800 |

32 |

260 |

25 |

16 |

22 |

15° |

| 900 |

36 |

260 |

25 |

16 |

22 |

15° |

| 1000 |

40 |

260/300 |

25 |

16 |

24 |

15° |

| 1100 |

44 |

300 |

25 |

16 |

24 |

15° |

| 1200 |

48 |

300 |

25 |

16 |

24 |

15° |

|

Note: If the medium is oil, acidic or alkaline substances, and there are special requirements for the working temperature, you can customize it by sending a letter or drawing. Please specify when ordering

|

Product Details

Production Flow

|

1.Raw material

Top level CR/EPDM/NBR

rubber raw materials,

No recycled rubber

|

2.Plasticating and mixing

Special Formulation for better Bending with Nylon,For Better Strength,Sealing

|

3.Workblanks wraping

Cooper plated steel wire reinforcement prevent pull off

|

|

4.Vulcanizing

Automatic vulcanization machine ensure vulcanization time and pressure

|

5.Inspecting

100% strict inspection is to be responsible for consumers

|

6. Packaging

Protective Packaging for No

Rust and Breakage

|

Application

PTFE expansion are widely used in various fields, including construction, chemical industry, shipbuilding, tap water, gas, chemical pipelines, petroleum pipelines, food pipelines, air conditioning pipelines, and sewage treatment.

Our Services

1.24-hour online

2.Free samples provided

3.Support customization

4.Provide drawings

5.Multiple payment styles to choose from

6.Factory inspection (material, specifications, quantity, pressure, packaging)

7.Long warranty period

8.Suitable packaging for transportation

Our Customer

Certificate

FAQ

Q1:What’s the material of PTFE expansion?

A1:The material can be EPDM,NBR,CR,SBR..It depends on the working condition.

Q2:What’s the warranty period of PTFE expansion?

A2:We provide 18 months’ warranty.

Q3:What’s the working temperature of PTFE expansion?

A3:The working temperature is -20℃~100℃.

Q4:What’s the package?

A4:The package is carton box and strong plywooden case.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!