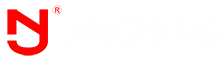

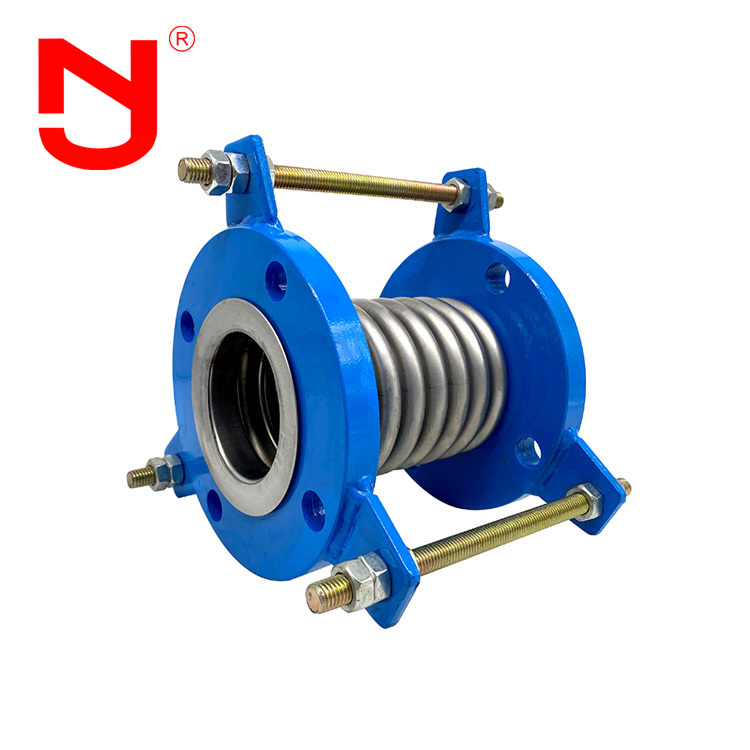

Steam Expansion Joints SS316 High Temperature Resistance

Steam expansion joints are specifically designed to withstand high-temperature steam environments while maintaining exceptional flexibility and durability. These joints effectively absorb thermal expansion and mechanical movements in steam piping systems, preventing stress buildup and potential damage. The use of SS316 material ensures outstanding resistance to corrosion and oxidation, even under prolonged exposure to aggressive steam conditions, making them ideal for applications in power plants, chemical processing facilities, and industrial steam networks where reliability and longevity are crucial.

Performance of Steam expansion joints

1. Good compensation effect

2. High temperature resistance

3. Metal dust boot can reduce leakage

4. Vibration resistance and high-speed performance

5. The specific pressure of the spring can be reduced

6. Possible torque transmission

7. Through certain structural design, the sealing failure caused by scaling can be reduced

Technique Parameter of Steam expansion joints

|

Main data of Steam expansion joints

|

|

|

|

Available Area of Bellows

(c㎡)

|

Max Size of External Diameter

(mm)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Production process of Steam expansion joints

Do you know how is a high quality Steam expansion joints made?Let's see with JINGNING.

Steam expansion joints can be processed into different types according to different needs

◆ Steam expansion joints Bellow Body: Stainless Steel 304, 316L.

◆ Steam expansion joints flange Materials: Q235 carbon steel, 304, 316L stainless steel.

Jingning has more than 17 years of design experience in manufacturing metal bellows, rubber expansion joint, metal bellows joint, disassembly joint, pipeline and other industrial pipe fittings. The metal bellows meets the international standards such as GB, ISO, DIN, ANSI, BS, JIS and the special requirements of customers.

Steam expansion joints advantages

1. Metal bellows is ex factory price

2. 17 years manufacturing experience, 5 years export experience

3. The metal bellows has strict quality inspection, and the quality far exceeds the industry standard.

4. Various specifications of metal bellows mold base customization and OEM

5. Free metal bellows samples

6. Large inventory of metal bellows

Steam expansion joints application

1. Pipeline deformation and deformation with large deformation of metal bellows and limited space position.

2. Large diameter pipeline with metal bellows has large deformation and displacement and low working pressure.

3. Steam expansion joints require devices to limit nozzle load.

4. Steam expansion joints are required to absorb or isolate high-frequency mechanical vibration.

5. Steam expansion joints are pipes required to absorb earthquake or foundation settlement.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!