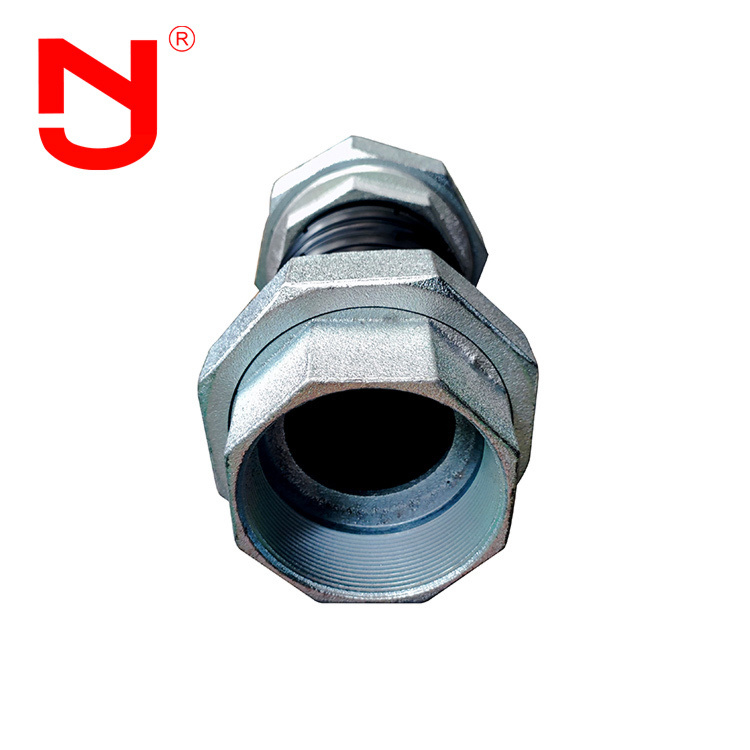

Stainless Steel Screwed Union Bspt Threaded Joint Expansion Joint Plumbing

Expansion joint plumbing is a flexible component designed to accommodate thermal expansion, contraction, vibrations, and misalignment in piping systems. It allows pipes to move axially, laterally, or angularly without causing stress, leaks, or structural damage. Typically constructed from materials like rubber, metal bellows, or PTFE, these joints are installed between pipe sections to absorb dimensional changes caused by temperature fluctuations, pressure variations, or mechanical forces. By reducing stress on connected equipment (e.g., pumps, valves) and preventing pipe rupture, they ensure system longevity, efficiency, and safety in applications such as HVAC, water treatment, and industrial piping.

Performance characteristics of Expansion Joint Plumbing

1. Expansion joint plumbing has the advantages of small volume, light weight, good elasticity and convenient equipment maintenance;

2. Expansion joint plumbing can have lateral, axial and angular displacement, and is not limited by the non centering of the pipe and the non parallel of the flange.

3. With the increase of temperature, the NBR threaded expansion joint will expand and contract;

4. Expansion joint plumbing can reduce the noise transmitted by the structure and has a strong damping capacity;

5. According to different scenarios, the NBR threaded expansion joint with different rubber materials can more effectively prevent the corrosion of corrosive media on the inner wall of rubber joints, and improve the service life.

Technical data of Expansion Joint Plumbing

|

Main data of Expansion Joint Plumbing

|

|

|

|

|

|

|

|

mm

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: 1. The special requirements of threaded rubber expansion joint can be customized according to the user's drawing. Flange standard is GB / t9115.1-2000. Various flange standards (GB, JB, Hg, CB, ANSI, DIN, BSEN, NF, en, JIS, ISO, etc.) can be selected for production. The rubber ball of threaded rubber expansion joint can be used as natural rubber, ethylene propylene diene monomer rubber, chloroprene rubber, butyl rubber, butadiene rubber, fluorine rubber, etc. When the threaded rubber expansion joint above DN200 is used for suspended water supply, the pipe must have fixed support or fixed support, otherwise the threaded rubber expansion joint shall be installed with anti falling device.

Expansion Joint Plumbing details show

Expansion Joint Plumbing production Flow

Do you know how is a Expansion Joint Plumbing made?Let's see with JINGNING.

It is very important to select the appropriate threaded rubber expansion joint of the pipeline, understand the compatibility of the medium with the selected material, the full temperature, pressure and vacuum range, the required movement and the size between the pipeline flanges. With this information, Jingning application engineers can help determine the ideal Expansion joint plumbing for any application.

Expansion Joint Plumbing advantage

1. Expansion joint plumbing is galvanized for 15 minutes, resistant to high pressure, high temperature, oil, wear, corrosion, acid and alkali.

2. Expansion joint plumbing are connected with pumps, valves, fire-fighting equipment, pipes with large vibration and pipes with frequent changes of cold and heat.

3. The natural rubber content of NBR threaded expansion joint is 47%, which can be used continuously for 15 years without aging.

We introduce foreign advanced technology and combine with China's production experience. In the Bspt threaded expansion joint manufacturing operation, the inner side bears high pressure, and the nylon cord and the inner side rubber are combined better, which can bear higher pressure than the ordinary Threaded Duct Expansion Joint. Threaded Duct Expansion Joint is characterized by perfect combination of inner rubber layer, bright, clean and seamless; the label of NBR threaded expansion joint adopts vulcanization process, which perfectly matches the ball of Threaded Duct Expansion Joint.

Expansion Joint Plumbing application

Expansion joint plumbing can be widely used in water supply and drainage, circulating water, HVAC, fire protection, paper making, pharmaceutical, petrochemical, ship piping system, water pump, compressor, fan and other piping systems. Ordinary Threaded Duct Expansion Joint is used to transport - 15 ℃ - 115 ℃ air, compressed air, water, water, seawater, oil, acid and alkali. Special type Threaded Duct Expansion Joint is used to transport medium, oil or strong alkali, strong acid and solid materials above - 30 ° C to 250 ° C.

FAQ

Q1: What`s the rubber material?

A1: EPDM,CR,NBR,etc.

Q2: Can you provide material certificate 3.1?

A2: Yes,we could provide material certificate 3.1.Please contact us to get the sample of material certificate 3.1.

Q3: What’s the material of flange ( retaining rings )?

A3: The material of flange can be carbon steel, stainless steel and ductile iron.

Q4: What is the MOQ ?

A4: 1 Piece.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!