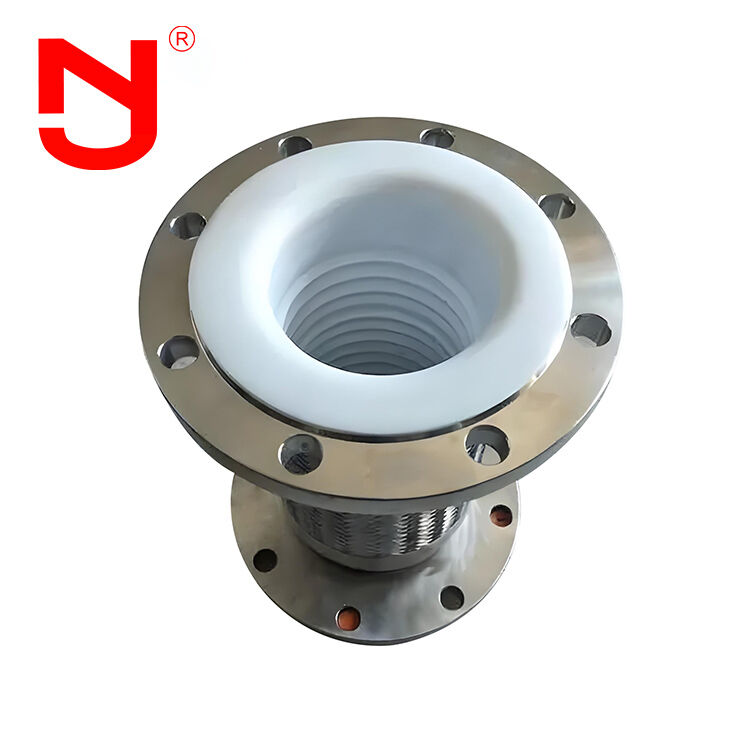

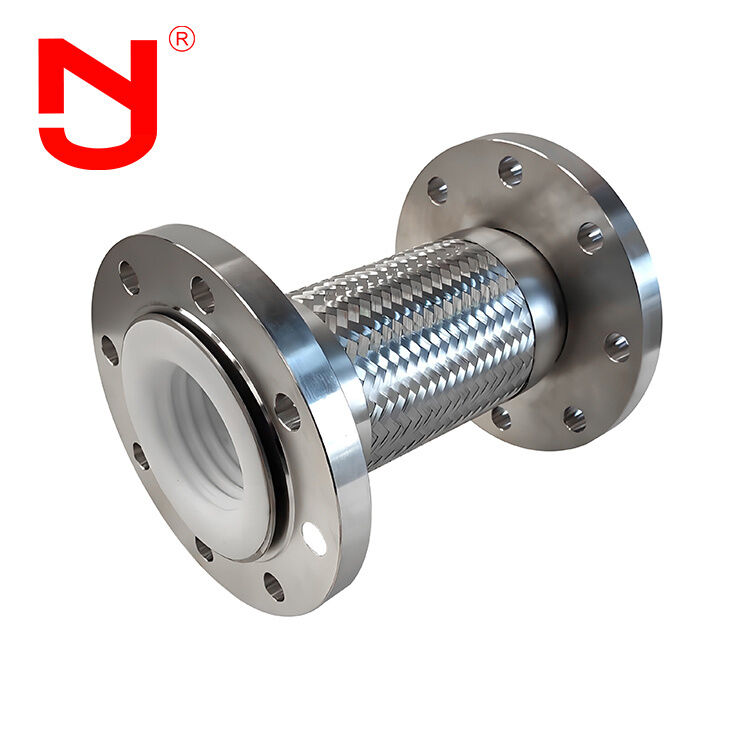

PTFE Lining Flexible Steel Corrugated Metal Hose

PTFE Lining Stainless Steel DN25 Braided Steel Hose Corrugated Metal Hose for Industrial Applications

This braided steel hose is a premium flexible piping solution engineered for demanding industrial applications. The PTFE inner lining provides exceptional resistance to corrosion, chemicals, and high temperatures while ensuring smooth flow and superior cleanliness. The corrugated stainless steel construction offers excellent flexibility and fatigue resistance, complemented by an external braided steel layer that reinforces pressure strength and mechanical protection. Ideal for chemical processing, oil & gas, pharmaceuticals, food industry, and high-purity fluid transmission systems.

Gas Hose Performance Characteristics

The primary elastic component of our flexible expansion joint is the stainless steel bellows. Through expansion and bending capabilities, the joint accommodates pipeline movements in axial, transverse, and angular directions. Key functions include:

- Absorbing axial, transverse, and angular thermal deformation in pipelines

- Reducing equipment vibration impact on pipeline systems

- Compensating for pipeline deformation caused by seismic events and ground settlement

Technical Specifications - Braided Steel Hose

| Diameter (mm) |

Pressure Grade (Mpa) |

Available Area of Bellows (cm²) |

Max External Diameter (mm) |

Length (mm) |

| 32 |

1.0/1.6/2.5 |

16 |

225 |

160-250/264-280 |

| 40 |

1.0/1.6/2.5 |

23 |

244 |

164-259/269-289 |

| 50 |

1.0/1.6/2.5 |

37 |

259 |

172-276/282-306 |

| 65 |

1.0/1.6/2.5 |

55 |

270 |

215-294/300-322 |

| 80 |

1.0/1.6/2.5 |

81 |

284 |

240-338/344-366 |

| 100 |

1.0/1.6/2.5 |

121 |

304 |

235-317/323-345 |

| 125 |

1.0/1.6/2.5 |

180 |

334 |

282-314/316-342 |

| 150 |

1.0/1.6/2.5 |

257 |

364 |

282-339/338-367 |

| 200 |

1.0/1.6/2.5 |

479 |

442 |

340-402/402-426 |

| 250 |

1.0/1.6/2.5 |

769 |

507 |

393-459/493-399 |

| 300 |

1.0/1.6/2.5 |

1105 |

562 |

464-525/564-565 |

| 350 |

1.0/1.6/2.5 |

1307 |

622 |

509-564/609-604 |

| 400 |

1.0/1.6/2.5 |

1611 |

562 |

522-566/622-628 |

| 450 |

1.0/1.6/2.5 |

1972 |

700 |

403-498/503-523 |

| 500 |

1.0/1.6/2.5 |

2445 |

760 |

431-523/531-554 |

| 600 |

1.0/1.6/2.5 |

3534 |

835 |

478-548/578-588 |

| 700 |

1.0/1.6/2.5 |

4717 |

1110 |

490/590 |

| 800 |

1.0/1.6/2.5 |

5822 |

1265 |

502/602 |

| 900 |

1.0/1.6/2.5 |

7620 |

1186 |

/698 |

| 1000 |

1.0/1.6/2.5 |

9043 |

1286 |

/692 |

PTFE Lined Metal Hose Manufacturing Process

Discover how JINGNING produces high-quality PTFE lined metal hoses with over 20 years of manufacturing expertise.

Our braided steel hoses are customized to meet diverse application requirements:

- Bellow Body Materials: Stainless Steel 304, 316L

- Flange Materials: Q235 carbon steel, 304, 316L stainless steel

JINGNING brings over two decades of design experience in manufacturing flexible expansion joints, rubber expansion joints, metal bellows joints, disassembly joints, and industrial pipe fittings. Our products comply with international standards including GB, ISO, DIN, ANSI, BS, JIS, and custom specifications.

Product Advantages

- Competitive factory-direct pricing

- 17 years manufacturing experience with 5 years export expertise

- Rigorous quality inspection exceeding industry standards

- Custom mold base customization and OEM services

- Free flexible hose pipe samples available

- Extensive inventory of flexible hose pipes

Application Areas

Our gas hoses compensate for temperature differential deformation and other movements between equipment and pipelines, prevent vibration, reduce pipeline thrust on equipment, and accommodate uneven tank foundation settlement. Widely utilized across chemical, oil refining, power generation, light industry, nuclear energy, metallurgy, machinery, instrumentation, marine, and aerospace sectors. With increasing applications in power and heat pipelines across industrial and civil fields, demand for high-performance gas hoses continues to grow.

Frequently Asked Questions

Q1: Can the Braided Steel Hose be marked with customized logo?

A1: Yes, custom logo marking is available. We provide comprehensive OEM & ODM services.

Q2: What's the face to face length of Braided Steel Hose?

A2: Standard lengths include L130, L152, L203. Custom lengths are available according to your specifications.

Q3: Can you provide drawings of gas hose?

A3: Yes, we provide detailed technical drawings. Please contact us for specific braided steel hose documentation.

Q4: What certificates of Braided Steel Hose can you provide?

A4: We provide CE and ISO certification for our products.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!